Hand down the process of soy sauce from each region worldwide

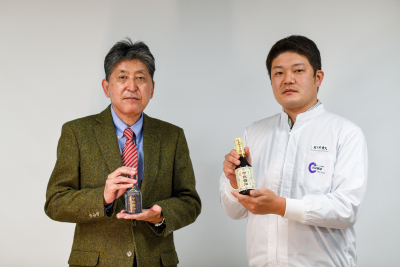

Iida Kyosuke, Sasaki Yuta, and Bob Florence

President of Chiba SHOYU Company / CEO of Haley Brook Foods Company

”170 year progress of the fermentation and soysauce culture” still continues today worldwide

Founded in 1854. The wooden tub that has been used for 170 years since the Edo period has kept the traditional soy sauce brewing made in the wooden tub over time. While inheriting the tradition, Kyosuke Iida, the current president, is constantly making new efforts. Currently, there are about 1150 soy sauce makers in Japan. Six major companies account for about 60% of sales, followed by nine second-tier companies, which are the top 15 companies, accounting for about 75% of the oligopoly industry. President Iida had a strong sense of crisis that we would not grow if we were doing the same things as major and second-tier companies. As one of the breakthrough measures, we have taken on the challenge of full-scale overseas expansion business since the 1960s.

Chapter.01 Pursuing the potential of soy sauce culture and opening the largest door to the world.

Chiba Soy Sauce is currently focusing on commercial soy sauce brewing, and is also making unique attempts such as manufacturing noodle soy sauce and sauce using soy sauce, and OEM development of Michelin-starred restaurants. In 2006, we developed “”Shimosa Soy Sauce””, which is brewed in a wooden tub with a volume of 8,000 liters, which has been used since its establishment, using only carefully selected domestically produced whole soybeans, wheat, and salt. It was featured in the gourmet magazine “”dancyu”” as “”Pikaichi’s most popular soy sauce””, and is known as a versatile type of soy sauce that is recognized by food professionals even in Chiba prefecture, which has the highest soy sauce production in Japan. Also, the late actor, Haruma Miura, is interested in “”fermentation”” and wants to see the soy sauce making since the Edo period, so she is interviewing Chiba Soy Sauce herself.

(Book “”Made in Japan”” Haruma Miura)

Originally, Chiba Soy Sauce was formed in 1964 by the merger of two soy sauce companies, Omuraya Shoten and Iida Sajibei Shoten. President Iida was born as the eldest son of the Iida family at his home on the factory grounds, and grew up watching the rise and fall of the soy sauce industry from his childhood.

Soy sauce is familiar to us, but Japanese household consumption is declining. Domestic consumption of soy sauce peaked in the 30’s of the Showa era and has been steadily declining. Currently, even in Chiba Prefecture, the kingdom of soy sauce, there are about 10 soy sauce makers that start making soy sauce. In the commercial business as well, price competition is intensifying due to oversupply. President Iida, who felt that he could not make the most of his strengths in the business of going under the price, began to look overseas in the 1960s.

At that time, processing of eel kabayaki, yakitori, tsukudani, fish, etc. was widespread in China and Southeast Asia. The soy sauce industry, which was seeking commercial demand such as exporting 10,000 tons of eel sauce, was paying attention to the overseas production of Japanese food products.

Actually, the DNA of overseas expansion is imprinted on Chiba soy sauce. In 1902, Iida Sajibei Shoten tried to produce soy sauce in Hawaii, and in 1945, Omuraya opened a soy sauce and miso factory in present-day China and was open until the end of the war. ..

Inheriting the DNA of the previous owner, President Iida exhibited at a food exhibition held in Shanghai, China in 2007. Taking this opportunity, he has been exhibiting in Taiwan, Singapore, Russia, etc., and has been exporting to China such as “”Dashi soy sauce for babies”” and “”Kaede for ramen””.

Chapter.02 Proactive activities brought two a fateful encounterin the U.S.

Transactions with Taiwan and China were banned from export due to radioactive contamination caused by the Great Tohoku Earthquake in 2011, and did not grow significantly as a business. However, the company turned its next business direction to the ASEAN region.

In 2007 and 2013, Shimosa Soy Sauce received two stars in the iTQi Contest (International Taste and Quality Examination Committee). While strengthening branding, President Iida gave a keynote speech entitled “”History and Current Status of Japanese Soy Sauce”” at the “”Indonesia-Japan Joint Science Symposium”” held in Indonesia in October 2014. In 2013, we obtained Halal certification and launched the soy sauce “”Halal Koiguchi Soy Sauce”” for Muslims, and also developed spicy soy sauce for Mongolia. In Germany, we provide Chiba soy sauce products to Michelin-starred restaurants through a trading company specializing in Japanese ingredients.

These overseas activities have created worldwide social contributions. In 2019, Bob Florence, Owner of Mystic Koji LLC, which is currently working on the development of fermented foods such as soy sauce and miso in Mystic, Connecticut, USA, suddenly sent an email saying “”I want to learn fermentation and brewing techniques.”” There was.

“”I was a chemist and was interested in fermentation and soy sauce. I contacted 15 Japanese soy sauce companies, but Mr. Iida showed a particularly positive interest in learning more about what we were doing in the United States”” says Bob.

“”I went to Japan many times to learn the technique of Chiba soy sauce and had them try the soy sauce I made. As a result of trial and error, it was commercialized but we have made steady improvements with the kind assistance of Mr. Iida and Chiba Shoyu. At first, I was using soybeans from the midwestern United States. Now our business has grown to the point where we are developing local soybean farming. I want to make the ingredients local and make craft soy sauce with local flavors all over the United States. I want to spread craft soy sauce to the United States and interact with Japan to create a new soy sauce culture. “” (Mr. Bob)

With President Iida’s overseas expansion, fermentation and soy sauce have been handed down to Mr. Bob, and a new culture has begun to emerge from Mr. Bob.

Chapter.03 Strategy and manufacturing. Continue to challenge new markets while inheriting the traditions to be preserved

While making steady efforts, President Iida is now calmly analyzing overseas expansion. “”The value of soy sauce is different between overseas and Japan. No matter how high quality soy sauce is made, it will not sell if the price is high. Moreover, major companies have already entered the market in North America, Thailand, Singapore, etc.”” Therefore, President Iida is paying new attention to India.

“”All Indian soybeans are not genetically modified, so there is a basis for making good soy sauce. We will pour our long history of soy sauce making and the know-how we have developed overseas, and bring a new soy sauce culture overseas. I would like to seriously think about ways to take root. The wealthy people in India who have local Japanese restaurants are very interested in soy sauce, and they communicate with them and the possibilities of soy sauce. I want to further expand. “” The road to next success is just around the corner. Although calm, it was the moment when I saw the passionate and strong aspirations of a 170-year-old venture company.

Another strength of Chiba soy sauce. It is my thoughts on manufacturing by Yudai Sasaki, the director of the brewing department, who supports President Iida, who is actively managing the company, and supports Chiba soy sauce. “”Soy sauce is made from microorganisms called Jiuqu, but I make soy sauce with the feeling of talking to the microorganisms every day. Nowadays, soy sauce made from stainless steel tubs is increasing, but Shimosa soy sauce is used. Various microorganisms live in old wooden tubs and promote fermentation. Since the bacteria that live in each brewery are different, the taste is also different for each tub. “” Director Sasaki grew up in an environment where he was exposed to food and food culture from a young age. That is why we have a love for the microorganisms that are indispensable for making soy sauce, and we are able to realize delicious soy sauce making that cannot be imitated anywhere else.

On the other hand, it is said that the number of craftsmen who can make wooden tubs, which are the source of soy sauce brewing, is steadily decreasing. The wooden tub is not just nostalgia, it is an important tool that determines the taste of soy sauce. “”I strongly feel that we must pass on the traditional soy sauce brewing to future generations in order to pass on the Japanese fermentation culture,”” says Sasaki. From his powerful message, we can see the issues that Cool Japan should work on together.

With the efforts of President Iida to spread soy sauce overseas, the movement of craft soy sauce has emerged in the United States, and Chiba soy sauce has played a very important role in the soy sauce industry. However, Chiba Soy Sauce did not expand overseas, and more soy sauce was created from the reliable technique of soy sauce brewing in a wooden tub, which has been handed down since the Edo period, and the passion for manufacturing such as Sasaki Brewing Manager. I think there are many offers from overseas because of the desire to deliver it to people in Japan.

Given that most small and medium-sized enterprises without large capital have an industrial structure in Japan, the history of the fighting of Chiba soy sauce is not limited to the soy sauce industry, but I think it will be a textbook for overseas expansion in any industry.

Written by・Kotaro Kashihara Edited by・Mariko Kita

Interview Date: Jan.25.2022

The content of this article is as of the interview date.

Chiba Shoyu Information website: https://www.chibashoyu.com/english/index.html

MOROMI Information website: https://moromishoyu.com/